PRODUCTS

We have sales experience and technology related to semiconductor and FPD

Engineering Material

POLYMOND

- Features

- Super durability

- High polishing rate

- Excellent process stability

Description

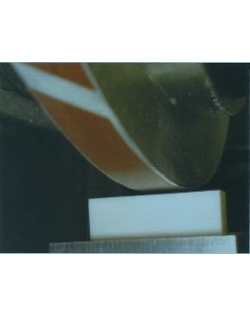

The excellence of POLYMOND comes from the original manufacturing method: the "Stirred and Mixed method". Diamond grits are mixed and stirred with Polymide, a resin highly resistant to high heat and chemicals. Diamond coated type films are used up when grits coated on the surface are worn out. However, the "Stirred and Mixed" type films can contain grits within the resin, so you might exhaust a film from top to bottom. Furthermore, Polymide resin is excellent in grit retention, which contributes to the high lapping performance.

Features

| Super durability | POLYMOND can polish 8,000 minutes and a longer than other films |

| High polishing rate | 1.7 times more polishing rate than a competitor |

| Excellent process stability | "Stirred and Mixed" method stably realizes a good surface roughness |

Applications

| Catagories | Example |

| 1. Haircutting:Nail nipper sharpner 2. Medical Use:Dental instruments, polishing micro lenses 3. Communication:Polishing optical fibers, polishing communication connetor 4. Ceramics:Ceramics machining, finishing termal sprayed ceramics 5. Semiconductors and equipment:Ceramics cleaning, roughening bumps, silicon wafers, fixing stepper, maintaining stamper, fixing lapping machine 6. Glass and lenses:Glass cleaning, optical lens polishing 7. LED:Polishing equipments, flip chip bonder cleaning 8. Handcrafts:Polishing jeweries |

1. For sample preparation 2. New Sheet-type grinding wheel 3. Sharpening edge tools 4. POLYMOND with base materials 5. For polishing curved glass or meal materials 6. Tungsten Carbide, super and steel alloys, ceramics parts 7. Optic fiber and glass products, mirror finishing process of crystal and sapphire and other gems 8. Free-curved surfaces of irregular shaped products |

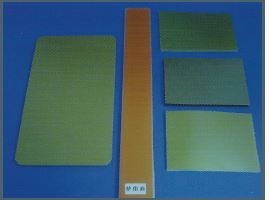

Spefications

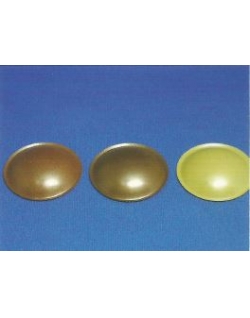

| Model | Particle Size | Thickness | Color | Dimension |

|---|---|---|---|---|

| SR80 | 200-240 μm | 250 μm | Black | ●Standard size 230x230mm ●Others 110x110mm 114114mm 230x460mm (manufacuture to other dimesions also possible) ●Adhesives type also available |

| SR100 | 170-200 μm | 200 μm | Yellow | |

| SR120 | 140-170 μm | 170 μm | Green | |

| SR200 | 85-100 μm | 100 μm | Orange | |

| SR280 | 65-75 μm | 90 μm | Moss green | |

| SR400 | 40-60 μm | 75 μm | Ocher yellow | |

| SR600 | 30-40 μm | 75 μm | Brown | |

| SR800 | 20-30 μm | 75 μm | Light green | |

| SR1000 | 10-20 μm | 75 μm | Dark brown | |

| SR1500 | 8-16 μm | 75 μm | Black | |

| SR3000 | 3-8 μm | 75 μm | Green | |

| SR5000 | 0.5-3 μm | 75 μm | Yellow green | |

| SR10000 | 0-1 μm | 75 μm | Yellow |